Co-extrusion Decking is the high-end option in the market. The coextruded decking itself is covered and protected by plastic shield and that’s where the name comes from.

Advanced performance in water absorption and scratch resistance is the main favor of Capped Decking, and various options in patterns and colors are the big plus for the decking.

Model :

CK21-140BSize :

21*140mmColor :

Standard colors or CustomizedBrand :

ForestFidelength :

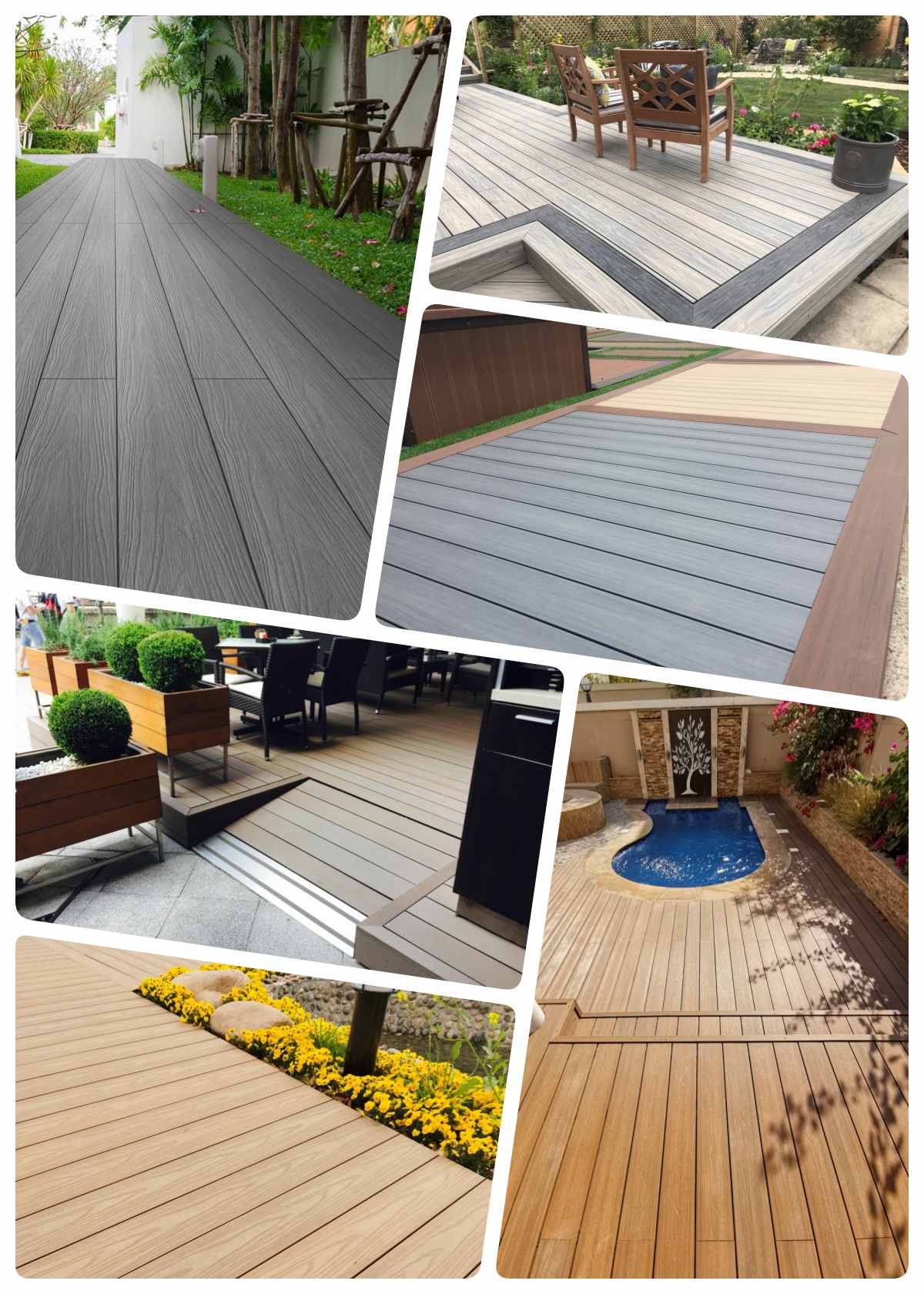

2.2m,2.8m,5.6m or CustomizedWPC decking skillfully blends the beauty of natural wood with the durability of plastic and is suitable for a wide range of environments. It not only effectively resists moisture and UV rays, ensuring no fading or deformation in the long term, but also has excellent resistance to insects and mold, reducing the need for routine maintenance.

Additional Information

| Brand | ForestFide |

| Name | WPC Decking |

| Model | CK21-140B |

| Standard Size | 21*140mm |

| Length | 2.2m,2.8m,5.6m or Customized |

| Material | Wood fiber Plastic Composite |

| Color | Standard colors or Customized |

| WPC Composition | 30% HDPE+60% Wood fiber+10% Chemical additives |

| Warranty | 10 years |

| Recycling | 100% recyclable |

| Package | Pallet or bulk packing |

| Payment | 30% deposited, the rest should be paid before deliver |

Package

Why Choose Us-ForestFide

Environmentally Protection

Our products are made of high-density polyethylene and wood fiber powder through a special process, which not only reduces the dependence on forest resources, but also effectively recycles waste plastics and reduces environmental pollution.

Durability

Compared to traditional wood, ForestFide's wood-plastic products are more resistant to water, corrosion, and insects, making them suitable for a wide range of harsh environments and lasting longer.

Aesthetics

We use unique texture design and color matching, which makes the products have the warm and natural feeling of wood, but also show the exquisite beauty of modern technology.

Customizability

Provide personalized customization service, customers can choose the color, texture and size according to their own needs, to create a unique wood-plastic products.

FAQ

1.What is WPC co-extrusion?

Co-extrusion of wood-plastic panels is a production process in which two or more different materials are co-extruded with wood powder or wood chips to make plastic wood products. Among them, the surface layer of high-density polyethylene (HDPE) and other plastics, the internal filling of wood powder, wood chips or other natural fibers, high temperature extrusion molding. Compared with traditional WPC, WPC co-extrusion has better durability, stability and aesthetics.

2.How do you clean WPC decking?

Use mop-dry or wet mopping to clean, avoiding the use of excessive water.

Use normal cleaning detergents, taking care to avoid strong acid and alkali cleaners.

3.Is WPC good for outdoor?

WPC panels are more weather-resistant and stable, and will not deform, crack, or suffer from termites, rot, or other problems due to sun and rain. This allows WPCs to maintain their beauty and functionality in outdoor environments for a long time.